Tactile Sensors And Tactile Sensing Technology

What is tactile sensing?

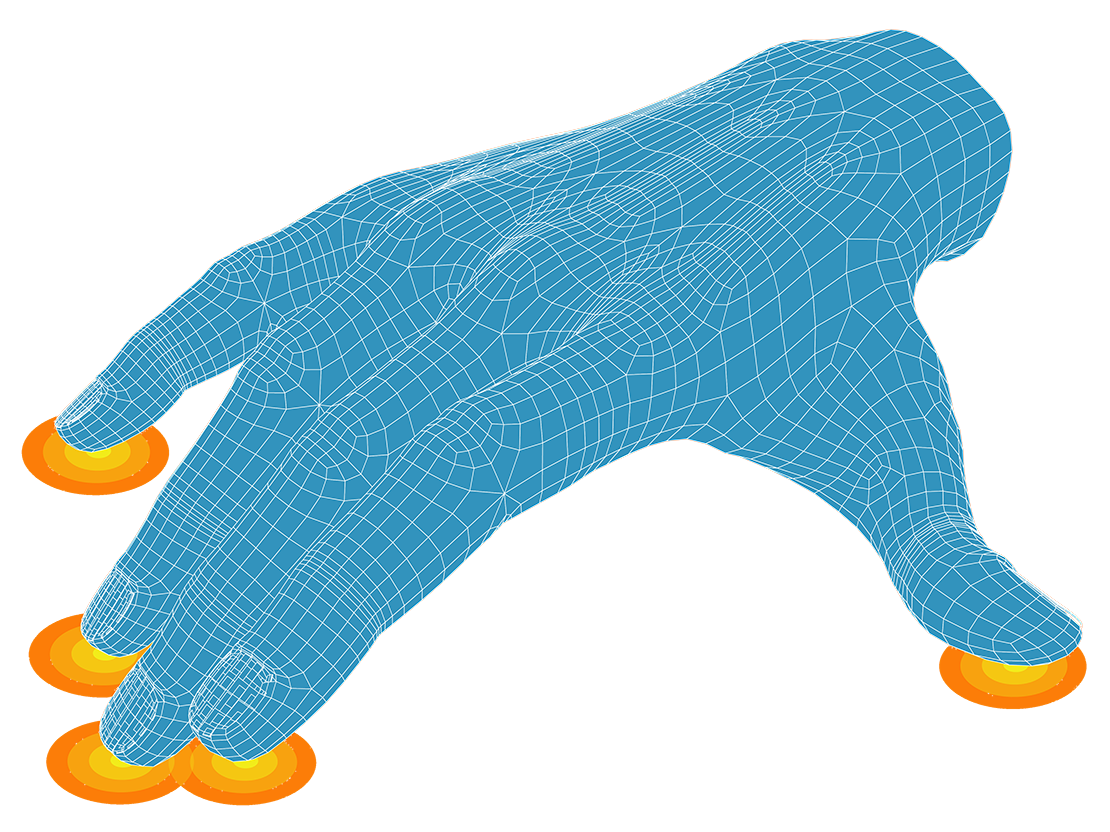

Tactile sensing relates to mapping contact pressures across a surface, often across complex surfaces like the hand, head, and other human body parts.

‘Pressure’ and ‘force’ are related to ‘tactile’ but do not capture the full complexity of contact mechanics. ‘Pressure’ captures solely magnitude and ‘force’ captures both magnitude and direction. Tactile measurement goes further by portraying the magnitude and distribution of contact pressures between two objects over an area as a matrix. This is achieved by using sensing elements that create a grid system to accurately detect pressure distribution, enhancing the precision of measurements in tactile sensing applications.

How does tactile sensing work?

There are two main types of sensors: capacitance-based or resistance-based (piezoresistive sensors). Capacitive sensors work by measuring changes in the gap distance between two electrodes; whereas resistive sensors measure changes in the resistance of a semi-conductive material.

What is Capacitance?

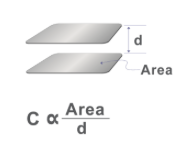

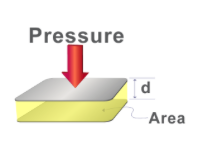

Capacitance is a measure of an object’s ability to store electrical charge and has been demonstrated countless times through the classic physics class example of two electrodes with area A separated by an air gap D as shown. As the air gap decreases, the capacitance C increases.

We use this property to build sensor pads and arrays by separating the electrodes using a proprietary compressible dielectric matrix, which acts as a spring. Precision manufacturing techniques allow excellent repeatability and sensitivity, while advanced conductive materials allow for conformable, stretchable, industrial, and other hybrid sensor designs. The simplicity of the capacitive sensor design gives us a large degree of flexibility when creating custom sensor solutions.

Comparison of Tactile Sensors

Swipe to compare →

| Capacitive Tactile Sensors | Resistive Tactile Sensors | |

|---|---|---|

| Construction | Conductive material separated by compressible dielectric |

Resistive ink printed on membrane |

| Sensitivity | Excellent | Fair |

| Repeatability | Excellent | Poor |

| Number of Elements | Good | Excellent |

| Design Flexibility | Excellent | Fair |

| Speed | Fair | Excellent |

| Temperature Stability | Excellent | Fair |

Capacitive tactile sensors

A capacitive tactile sensor is a sensor technology that is used to detect changes in capacitance caused by direct contact from touch, pressure, or force applied to the sensing face.

They typically consist of at least two metal electrodes and a compressible dielectric material. When pressure is applied to the sensor sensing face from physical contact with the sensor, the distance between the metal plate electrodes changes, altering the capacitance, which is then measured by a dedicated capacitance sensor/meter and translated into meaningful data by an electronic device.

The sensing range can be easily controlled by altering the dielectric constant between the two plates and/or the geometry of the sensor sensing face during the sensor design phase. This means a tactile capacitive sensor is applicable in a wide range of applications, from feather touch to heavy industrial.

Research from Institut Pascal - Université Clermont Auvergne demonstrates capacitive tactile sensing is often preferred to resistive alternatives for capturing contact pressure measurement changes due to sensitivity, repeatability, stability and design flexibility. This conclusion is echoed by work at the University of Manchester and University of Oxford, which show that capacitive tactile systems deliver superior linearity, adaptability and long-term stability in many tactile and pressure-mapping applications.”

Measuring comfort and fit with ergonomic sensing technology

Ergonomic design depends on understanding how people physically interact with products. PPS tactile sensors deliver detailed pressure maps that reveal exactly where discomfort, pressure points, or poor fit occur.

Whether optimizing automotive seating, improving wearable comfort or validating medical device interfaces, tactile sensing technology enables engineers and designers to quantify comfort with scientific precision.

Tactile capacitive sensors, with their flexibility and immunity to external capacitance and EMI, are excellent options for use in ergonomic design.

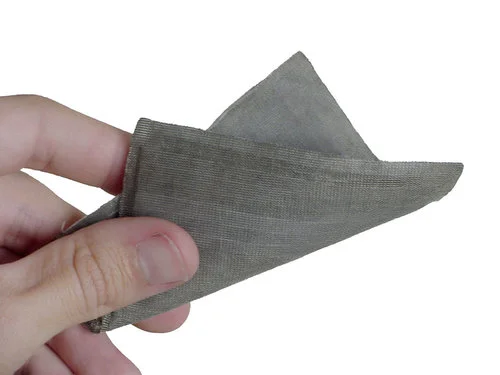

Capable of conforming to complex geometry, and available in customisable form factors, tactile sensors provide accurate and interpretable results in a wide range of human body interactions such as the hand, and head. These can help assess safety standards, design comfortable consumer products, as well as medical and ergonomic research.

Tactile sensor technology applications

Medical devices

In medical device design and development, tactile sensors are revolutionizing the way devices simulate the sense of touch. These sensors are crucial for creating training and treatment devices that enhance the accuracy and effectiveness of medical procedures. For example, prosthetic limbs equipped with tactile sensors can provide users with a sense of touch, enabling more natural and intuitive control. This advancement not only improves the functionality of prosthetics but also significantly enhances the quality of life for users.

Additionally, capacitive pressure sensors are used in medical and wearable devices. For example, researchers at Stanford University developed an ultra-thin, skin-conformable capacitive pressure sensor for continuous monitoring of arterial blood pressure in neonates. Another team at Massachusetts Institute of Technology built a wearable blood-pressure monitor capable of 24-hour continuous monitoring without a cuff. Together, these studies demonstrate that capacitive sensors can operate over broad pressure ranges, offer high sensitivity and repeatability, and are well suited for real-time feedback in health-monitoring applications.

Foot function and gait analysis

In foot function and gait analysis, tactile sensors are used to measure pressure distribution and other parameters that are vital for diagnosing and treating conditions such as diabetes and arthritis. These sensors can detect changes in pressure distribution, providing early indicators of potential issues. For example, insoles embedded with tactile sensors can monitor pressure distribution across the foot, offering valuable feedback to prevent injuries and improve overall foot health.

A study from the University of Leeds saw a team develop sensor technology capable of measuring forces at the sole of the foot. The results revealed such technology is particularly beneficial for helping individuals at risk from foot disease, especially for individuals with diabetes to help preventing foot ulcers and other complications.

Hand-Tool Comfort and Grip Analysis

Ergonomic tool design starts with understanding how force is applied by the hand. PPS’s technology measures pressure and shear across tool handles, gloves, and control surfaces, creating high-resolution “grip maps” that reveal exactly how users interact with a product.

Engineers can use this data to refine handle geometry, texture, and material stiffness, which reduces localized strain and fatigue while improving control and safety.

PPS’s tactile sensors wrap around curved handles and irregular surfaces, enabling accurate testing of real-world grip dynamics. The result: tools that are not only efficient but comfortable and intuitive for extended use.

Robotic Grasping and Manipulation

Tactile sensors help robots to interact with their environment and handle objects with precision. These sensors detect pressure distribution, force, and other critical parameters, allowing robots to perform tasks that require dexterity and accuracy. For instance, a robotic finger equipped with tactile sensors can adjust its grip based on the object’s texture and shape, ensuring secure and delicate handling. This capability is essential for applications ranging from industrial automation to delicate surgical procedures.

Automotive Interior Design

In automotive design, ergonomics are all about how the drivers and passengers feel inside the vehicle. PPS tactile sensors enable engineers to measure and visualize pressure distributions across seats, armrests, headrests, steering wheels, and touch interfaces.

By analysing how users interact with surfaces and controls, OEMs can fine-tune foam density, fabric tension and component geometry to achieve consistent comfort and reduce fatigue.

PPS’s sensors support real-time testing under motion, temperature and vibration conditions. This delivers actionable data that helps companies engineer interiors with precision comfort and tactile quality.

In addition to these applications, tactile sensors are also utilized in various other fields for human interface design and for virtual reality. The ability to perceive and interpret tactile signals is essential for many applications, making tactile sensors a crucial component in advancing technology and improving human-machine interactions.

PPS Array Sensors

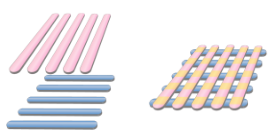

To build our Tactile Array Sensors, we arrange electrodes as orthogonal, overlapping strips separated by a proprietary compressible dielectric matrix, which acts as a spring. A distinct capacitor is formed at each point where the electrode strips overlap.

Precision manufacturing techniques allow excellent repeatability and sensitivity, while advanced conductive materials allow for conformable, stretchable, industrial, and other hybrid sensor designs.

By selectively scanning a single row and column, the capacitance, or local pressure, at that location is measured. Our proprietary drive and conditioning electronics can scan through an array at high speed while optimizing settings to achieve the maximum sensor response from each force sensing element

Industrial

Made for extreme temperatures and extreme pressures

Stretchable

Can be flexed and deformed while still maintaining data accuracy

Design Cycle for Tactile Sensors

Incorporating tactile sensors into products requires careful planning and an iterative design cycle. Moving from a concept to a commercialised product involves several stages, each requiring specific attention to detail.

The first step is to define the problem and describe the product's environment in detail. Since tactile sensors have many customizable parameters, including pressure range, size, materials, and temperature tolerance, getting these details right from the start is critical. Specificity in the design phase helps avoid costly delays during development. For example, pressure mapping for a bike seat could vary widely depending on whether it’s used for product design, biomechanical analysis, or rider customisation.

To ensure the custom sensor meets the application’s needs, one or two prototypes are often created. These prototypes allow us to test for specific use cases and identify any issues before scaling production. Once the prototype is proven, we move into a pilot production phase to ensure scalability and cost-effectiveness.

Validating Precision of PPS Tactile Sensors

Proving the accuracy of tactile sensors is essential in any industry. Calibrations play a key role in achieving accurate pressure measurements. No two sensors are exactly the same, meaning each sensor element might respond slightly differently to the same pressure. Calibration corrects these variations by deriving a coefficient that converts the raw sensor output into accurate pressure readings.

During calibration, a known pressure is applied to the sensor, and a calibration coefficient is determined. This ensures that each sensor responds accurately to varying pressures. The calibration process is crucial in applications where precise pressure measurement is vital, such as medical equipment or robotic systems.

One of the challenges of calibration is ensuring that the applied pressure is uniform. Inconsistent pressure can lead to inaccurate readings and calibration errors. To solve this, we use methods such as placing a sensor inside a chamber with a bladder that inflates to apply uniform pressure. This method ensures that the sensor is accurately calibrated across the entire pressure range.

For sensors used in dynamic environments, such as a windshield wiper blade, calibration must account for changing shapes and contact points. In such cases, a robotic calibration system simulates real-world conditions to ensure the sensor’s accuracy during actual use.

Tactile sensing technology offers unparalleled precision in measuring contact pressures. Capacitive tactile sensors stand out due to their sensitivity, stability, and design flexibility. Whether it's in a prototype phase or in full-scale production, the reliability of our tactile pressure sensors ensures they meet the highest performance standards. Through accurate calibration, our sensors provide the precise pressure data required for even the most demanding applications.

Case studies

Sports performance

Red Bull Surf Science partnered with PPS to explore new ways of enhancing athletes’ performance. Its team came to PPS to help provide it with critical insights into foot pressure during surfing to help measure how athletes drive and control their boards. With Pressure Sensing Surf Booties, surf coaches could measure and analyse pressure distribution in real time and after a session – outlining areas where pressure can be applied differently to enhance performance.

Comfort and shoe fit

Footwear testing and shoe performance brand Heeluxe approached PPS to help improve product consistency for footwear brands, and deliver a more reliable, comfortable fit. By integrating PPS’s tactile sensor technology, Heeluxe made shoe testing into a precise, data-driven system rather than a manual, time-intensive process.

Geoff Gray, Founder and Biomechanics Director of Heeluxe, said: “Tactile sensors are at the heart of how we translate human comfort into measurable data – they allow us to quantify something as subjective as shoe fit.”

Heeluxe SmartLast explained including the positioning of PPS SingleTact sensors within the last