Quantifying Hand Ergonomics With The Tactile Glove

Introduction

Musculoskeletal disorders (MSD) are injuries or disorders of the muscles, nerves, tendons, joints and cartilage. Work-related musculoskeletal disorders (WMSD) are conditions caused, prolonged or made worse by work conditions.

Ergonomics / human factors considers the interaction between humans and other parts of a system. A goal of ergonomics is to reduce stress and eliminate injuries and disorders associated with the overuse of muscles, bad posture, and repeated tasks. A workplace ergonomics program can aim to prevent or control injuries and illnesses by eliminating or reducing worker exposure to WMSD risk factors using engineering and administrative controls. Risk factors include awkward postures, repetition, material handling, force, mechanical compression and duration of exposure.

There is strong evidence that job tasks that require a combination of risk factors (e.g., highly repetitious, forceful hand/wrist exertions) increase risk for hand/wrist tendinitis. Fifty percent of industries reported work-related musculoskeletal disorders (WMSD) rely heavily on the use of hand tools.

A better understanding of the forces and effort on the hand in various tasks allows:

Ergonomics engineers to design better products

Clinicians to understand hand strength required for a given profession and

Safety regulators to specify standards for safe-working conditions.

The PPS TactileGlove enables the capture of natural high-resolution, dynamic, pressure mapping data to fully understand hand interactions.

Background

Until recently, there have been limited tools available to measure force distribution on the hand. These have been limited to hand dynamometers, pinch gauges and push/pull force gauges, as shown in Figure 1.

Figure 1 Traditional methods of hand force measurement (a): hand dynamometer, (b) pinch gauge, (c) push/pull force gauges.

This has made it difficult for government regulators, such as the UK Health and Safety Executive, to provide definitive limits on acceptable hand forces, instead relying on subjective terms such as light to moderate.

The PPS TactileGlove solves this problem by facilitating the measurement of repeatable, high resolution dynamic tactile data. The compact, wireless design introduces minimal obstruction to the user while performing their task. Measurement repeatability is achieved through the use of PPS’s capacitive sensing technology.

Figure 2. (a) The PPS TactileGlove being used for a task requiring god hand dexterity. (b) The inside of the TactileGlove showing the capacitive sensors.

Pressure Force and Tactile

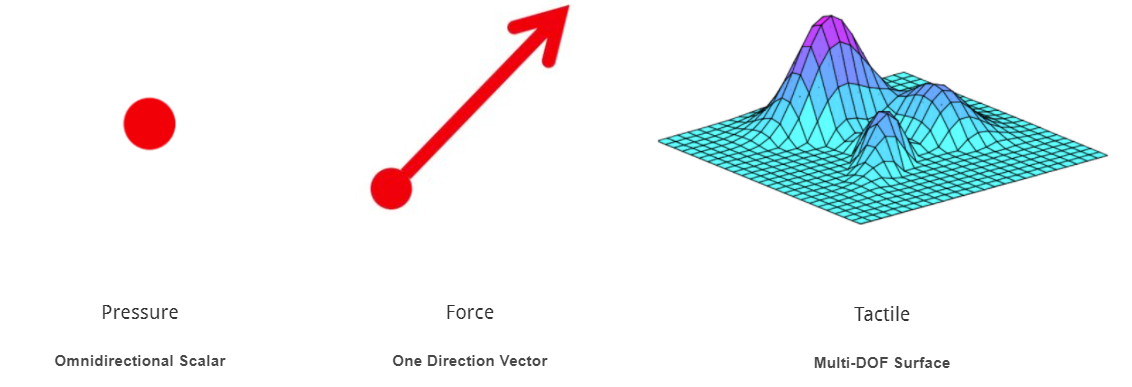

Tactile sensing relates to mapping contact pressures across a surface, often across complex surfaces like the hand. The more often-used terms "pressure" and "force" are related to "tactile," but both cannot capture the full complexity of contact mechanics. "Pressure" is a scalar value capturing solely magnitude and "force" is a vector expressing magnitude and direction. Tactile measurements plots the normal force or pressure over an area, which is represented as a matrix. This is illustrated below.

Figure 3: Press, Force and Tactile illustration

Quantifying Effort

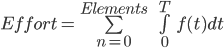

One factor that can be used to differentiate different tools is the total effort required for a process. We can define Effort (N.s) as the total force magnitude exerted by the hand over the task duration, and calculate it by summing the integral of all force measurements over time as shown below and illustrated in Figure 4.

Equation 1 Effort Equation.

Generally, easier to use tools require lower effort.

Figure 4: Effort is defined as the integral of total force over time, summed over all elements. So we add the area under each element curve.

We will now consider two tool examples, cutting and spreading.

Example 1: Sawing a 1” x 2” wood

As an illustrative example, four types of saw were each used to cut a 1” x 2” section of pine wood.

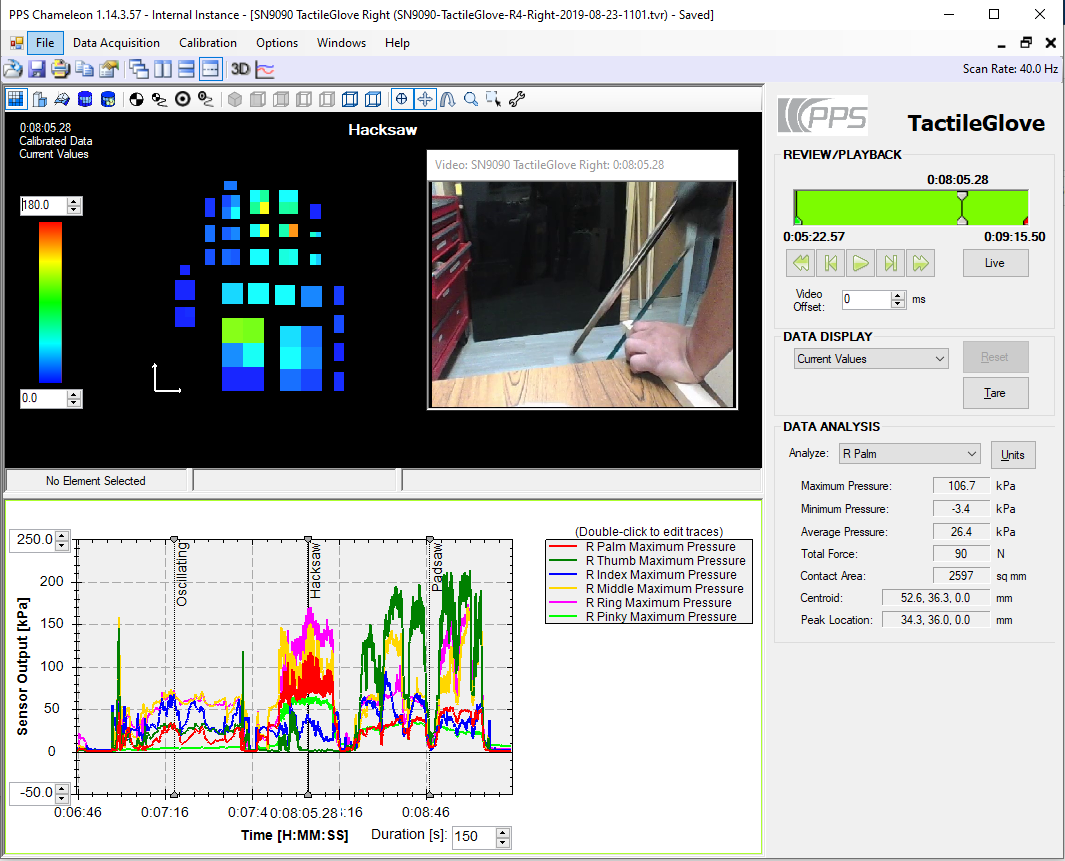

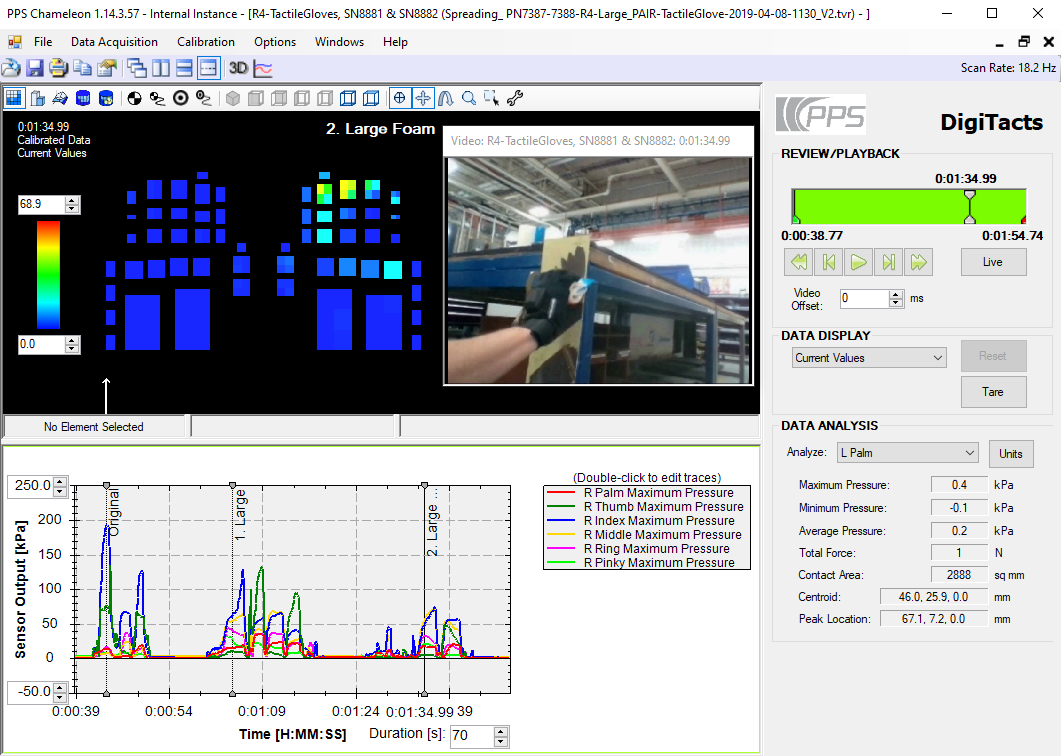

Tactile data from the TactileGlove is shown in Figure 5. There are two main views. The top view shows the pressure distribution at an instant in time, in this case during the use of the electric oscillating saw. Pressure is distributed mostly over the side of the index finger, base of the thumb and tips of the middle and ring fingers.

The bottom strip chart plots the maximum pressure on each digit over time. A data analytics pane in the bottom right gives an overview of key measurements, such as the total force measured by the glove, in this moment, 34 N. Synchronized video from a webcam is also shown which is useful to match actions with tactile measurements.

Figure 5: Example data captured by a PPS TactileGlove when sawing wood with several types of saw.

Simple analysis can be performed in Chameleon. For example, we can see with the oscillating saw, there is a pressure spike at the beginning and end of the operation, this is the result of pushing a stiff on/off slide switch. We can see the total force applied by each digit and look for pressure consentations. We can also plot both pressure and/or force for each element in the strip chart, in this case we are showing maximum pressure on each digit.

For more detailed analysis, we export the data to csv and process in Excel, Matlab or equivalent.

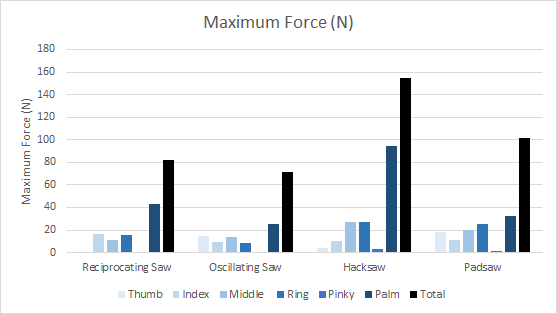

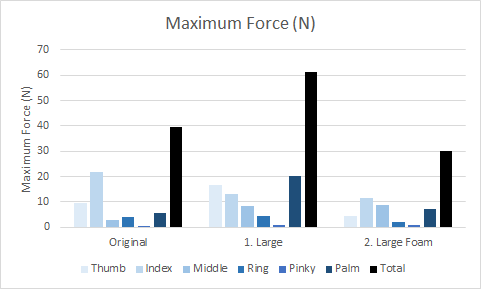

Figure 6: Maximum Digit Force

For example, Figure 6 plots the maximum total force on each digit for each saw type(excluding the switch force for the oscillating saw). The hacksaw exhibits the maximum force, mostly on the palm. Forces on the palm are likely more ergonomic than those on the digits. We can compare these force levels against any safety limits we may have for force on a particular digit.

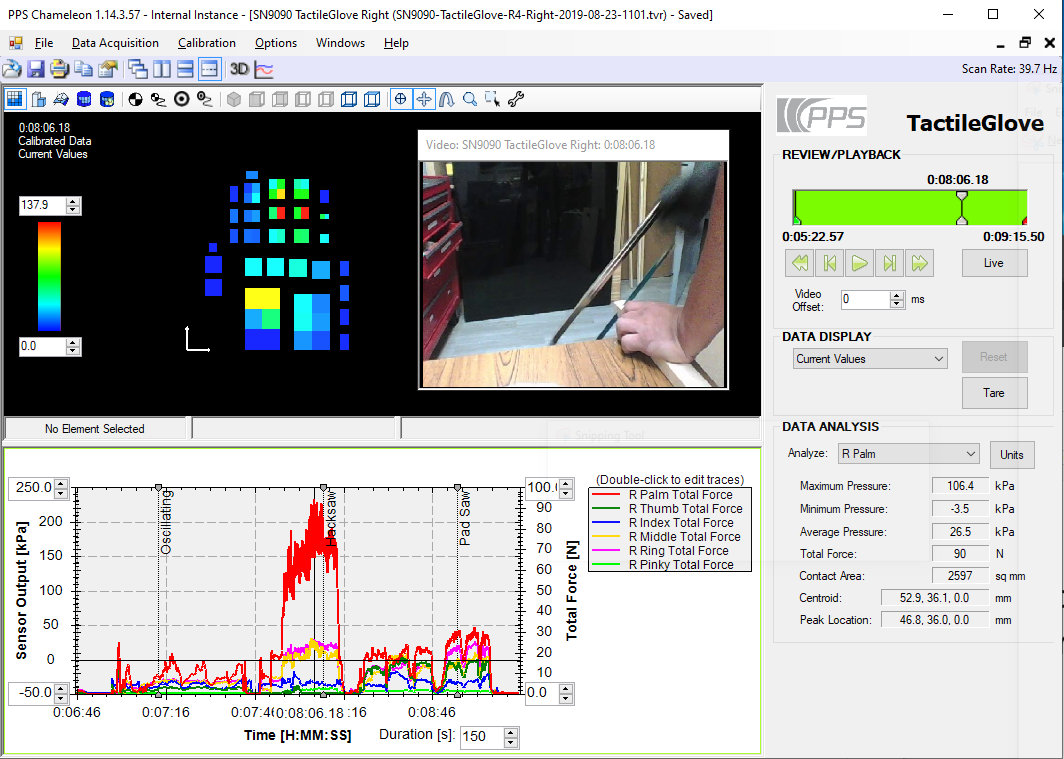

Figure 7: An example frame when sawing with the hacksaw. Total digit force is plotted in the strip chart.

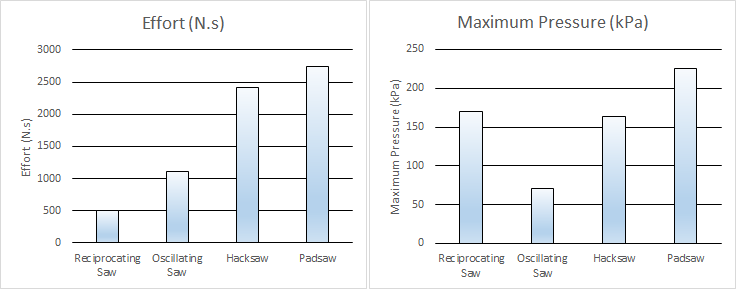

Figure 8: Left: Effort for each saw type as defined in Equation 1. Right Maximum pressure for each saw type

Considering Effort (Figure 8), we can see that the power assisted oscillating and reciprocal saw reduced the effort when compared to manual saws. The pad saw had relatively low peak forces on specific digits, but did require prolonged force, increasing the effort.

Lastly, if we consider maximum pressure (Figure 9), we can see the pad saw provides peak pressure, over 200 kPa. Cross referencing with Figure 5 we can see this occurs on the thumb and ring finger, which may cause discomfort over prolonged periods.

Let's now consider a second simple example.

Example 2: Spreading Handle Design

Spreading is used extensively in gluing, sealing and painting. It makes extensive use of pinching, pulling and pushing motions. Lets consider the goal of optimising the hand ergonomics of the spreader design. The original spreader has a very thin handle, making it uncomfortable to use. Design 1 has a large hard handle. Design 2 has a large foam handle, most similar to a bicycle handlebar. All three spreaders have the same active area for spreading. The test subject was asked to spread a fixed volume of sealant for each test.

Figure 10: Original spreader, followed by two prototypes aiming to improve the design

Figure 11: Example data captured by a PPS TactileGlove when using three different types of spreader.

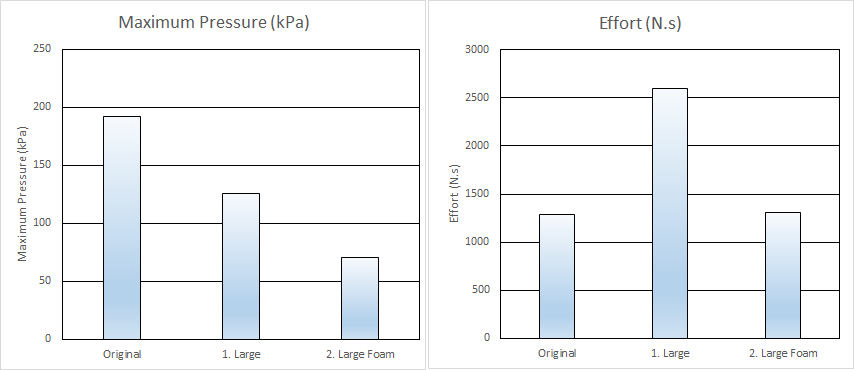

Figure 12: Plots of Effort, Maximum Pressure and Maximum Digit Force.

Two distinct forces are required to use the tool. Firstly a pinching force to hold the tool and secondly the lateral force to move the spreader around. We can look to minimise the pinching force required, through a better handle design. We can’t change the magnitude of the lateral force, but we can optimize where the force is exhibited on the hands.

By considering the results in Figure 12 we can see that both handle designs reduce the maximum pressure the operator experiences by spreading the load over a larger contact area. This makes them more comfortable to use. The handle in the new designs spreads the load more uniformly across the hand while providing a better grip, reducing the pinch force required to hold the tool. The foam spreads this load better, further reducing the peak pressure and digit force.

The effort plot is less easy to interpret in this case as it is harder to control the task duration for something like spreading.

Summary

This white paper has provided an overview of how the PPS TactileGlove can be used to quantify the ergonomics of hand tools and power tools. The concept of task effort was defined when considering human factors and ergonomics. The effort calculation clearly showed the reduced work required when using electric saws compared to hand saws. Digit force and peak pressures were also considered key design parameters and were used to clearly show the advantage of foam on a spreader handle. Hopefully, it is clear that none of the traditional tools outlined in Figure 1 provides a comparable insight into hand ergonomics.

To find out more please contact PPS Sales representatives.

Useful Reading and Support

Additional white papers for calibration/verification and application support can be found here:

WHITE PAPER - Interpreting TactileGlove Data for Practical Use Cases - Published 2024

WHITE PAPER - Calibrating and Verifying Tactile Pressure Sensors - Published 2018

SUCCESS STORY - Purdue Uni Research Project Assesses Lifting Injury Risks using PPS TactileGlove - May 2025

Details on TactileGlove specifications and intended use applications can be found here:

Force Measuring Sensor Glove | Grip & Hand Mapping

Pressure Mapping & Pressure Mapping Technology

Real examples of TactileGlove being used in research and development can be found here:

RESEARCH ARTICLE - Investigating Gripping Force During Lifting Tasks Using a Pressure Sensing Glove System - February 2023 - Purdue University - Download

RESEARCH ARTICLE - Identification of Adaptive Driving Style Preference through Implicit Inputs in SAE L2 Vehicles - November 2022 - Honda Research Institute USA, Inc - Download

RESEARCH ARTICLE (in Japanese) -Measurement and Assessment of Touch Skills during Dementia Care Movements Using Tactile Gloves - 2020 - Kyushu University