Headband Sensor System

The Headband Sensor System from PPS is a bike/ski sensor system used for assessing the size adjustment mechanism of helmets, allowing users to measure and visualize pressure points.

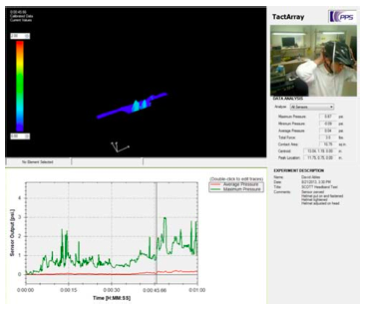

Headband Sensor System during Testing

Designed for companies that make helmets for ski or bikes, the Headband Sensor System is used by designers looking to balance fit and comfort in their helmet designs. The Headband Sensor System allows designers to quantify and visualize contact pressures deploying versatile designs and can accommodate a range of head sizes for mannequins or human subjects. The Headband Sensor System is the only sensor technology that can meet the requirements of this application given the requirement to resolve to low pressures and conform to complex shapes around the head without sacrificing accuracy or repeatability performance.

The Headband Sensor System includes one headband tactile sensor assembly that consists of two sensors, one on each side of the head, joined by an elastic band.

Using the included T4500 interface electronics with USB 2.0 to attach to a computer, the system runs PPS’s Chameleon image capture and analysis software. This industry-leading software is fully featured which means it can export replay, save test data, and perform analysis functions. Chameleon can also record and playback video with your data results for even greater insight and analysis.

KEY SYSTEM FEATURES AND BENEFITS:

The Sensor is designed as a band. Two sensors, one on each side of the head, joined by an elastic band create a sensor pattern that fully covers the headband region for valuable data collection about helmet comfort and fit.

High resolution, sensitive, and conformable sensor can collect data from a curved human head shape without sacrificing accuracy or reliability.

Sensors can capture extremely low pressures. Helmet pressures are typically very small but can cause severe discomfort during extended use, so high pressure resolution is needed.

Sensors are accurate and repeatable even for complex head shapes so users can quantify comfort and fit testing for optimized product design.

Optional API enables creation of custom visualization software.

High performance capacitive sensing technology saves time and improves results by significantly reducing recalibration and repeated tests allowing developers to resolve problems and answer questions faster. Twice the repeatability, 5x better minimum pressure detection, and 50% better pressure sensing resolution compared to typical resistive tactile sensor technologies.

Chameleon Visualization Software provides intuitive, easy to use, high-quality visualization, and easy access to data for analysis and export to other applications. The software is fully featured which means export, replay, save, and analysis functions are included with every system, unlike competitors who require a paid upgrade for these features.